The constant evolution in e-commerce and increasing consumer demands have developed intense pressure on warehouse operations. Today, modern fulfillment facilities must process orders with great speed and precision, which is often complex for traditional systems to accomplish. This is where artificial intelligence in warehouses has become more critical than ever, resulting in simplified warehouse processes, making high-volume order processing simpler, and offering measurable results across operations.

By connecting AI into warehouses, logistics, and fulfillment operations become smart, quick, and effortless. AI-driven warehouses can be a key advantage for modern supply chain managers to stay ahead of the curve. This will not just support fulfillment strategy alignment, but also transform high-volume order processing and fulfillment, and bring improvements in logistics and fulfillment.

74% of supply chain managers increased operational efficiency, performance, and ROI drastically by utilizing AI-powered logistics solutions. As customers’ expectations for timely and correct deliveries will continue to rise, demand for data-driven insights and personalized services is also increasing, making executing AI-powered fulfillment solutions more crucial than ever, ensuring sustainable, smooth, efficient, and reliable order fulfillment.

At Shiprelax, we’re proud to embrace this revolutionary evolution, integrating AI across the entire process, from sourcing to delivery. Our AI-led 3PL logistics platform and services are not just a tool, but a detailed and powerful approach to redefining global logistics.

This detailed guide explains how AI is transforming the logistics and fulfillment landscape and how modern companies can leverage this technology to optimize their logistics operations, reduce costs, enhance customer satisfaction, and ultimately thrive in a complex logistics environment.

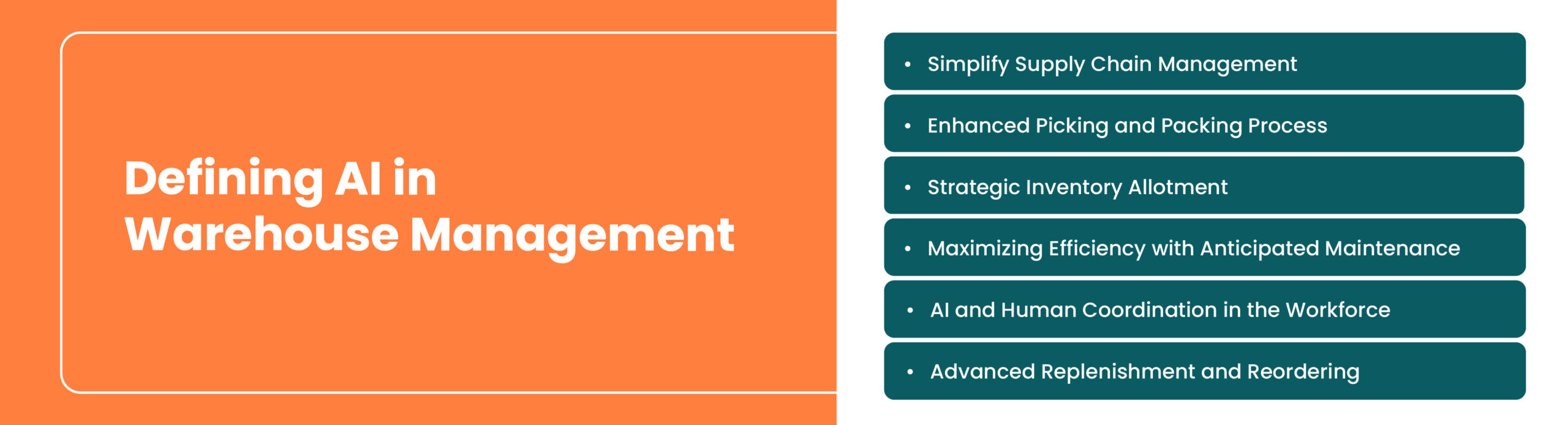

Defining AI in Warehouse Management

The core application of AI in the warehouse management system (WMS) is in the fulfillment phase, improving productivity and performance by aligning picking patterns and product placement, determining at-risk orders, and assisting in other fulfillment facilities to improve employee productivity and increase revenues. AI supports demand forecasting, responds to market constant changes, strategizes inventory counts, and ensures efficient warehouse operations.

- Simplify Supply Chain Management:

Traditionally, supply chain systems often face complexities such as inefficiencies and inaccuracies, resulting in late shipments, stock reductions, and overstocking. AI in the warehouse enables smooth inventory management by ensuring optimal stock levels and avoiding stockouts. It helps systemize and align every phase of fulfillment through real-time visibility, predicting future demands by assessing historical market trends and real-time sales information. AI applications in the supply chain even help identify the most efficient delivery routes by considering factors such as traffic patterns and delivery timeframes, enhancing delivery times and reducing transportation expenses. ShipRelax (a leading 3PL provider) embraces an AI-powered fulfillment solution to increase supply chain speed, accuracy, and performance.

- Enhanced Picking and Packing Process:

Picking and packing can account for up to 54% of warehouse labor costs, making it key for achieving AI-driven efficiency. AI transforms these functions through effective route optimization that reduces travel time within the warehouse. By analyzing layouts, product locations, and order details, AI optimizes picking routes, cutting travel time and boosting productivity. In advanced facilities, collaborative robots (cobots) assist workers with picking or transporting items, improving efficiency by up to 250–350% compared to traditional methods. - Strategic Inventory Allotment:

For multi-channel retailers, AI enables smooth and accurate inventory management and distribution. By evaluating sales data, historical trends, channel performance, promotional calendars, and seasonal patterns, AI identifies the best stock allocation strategy. These systems can adjust inventory in real time, especially during peak seasons, ensuring products are available where demand is highest. This intelligent, data-driven strategy helps minimize channel-specific stockout risks while reducing overstocking, resulting in better working capital utilization and improved inventory turnover.

- Maximizing Efficiency with Anticipated Maintenance:

AI isn’t just for inventory or robotics—it also predicts maintenance needs for warehouse equipment. By analyzing sensor data and machine performance, AI forecasts potential faults and schedules maintenance proactively to avoid costly downtime, ensuring uninterrupted warehouse operations. - AI and Human Coordination in the Workforce:

AI doesn’t replace human jobs—it creates a hybrid workforce where humans and machines collaborate for higher efficiency. AI-powered robots handle repetitive, labor-intensive tasks, freeing workers to focus on decision-making, creativity, and problem-solving. Moreover, AI enhances human productivity with data-driven analytics, reporting, and smart recommendations that support better business decisions. Technologies like augmented reality enable faster, more accurate picking and optimized workflows. This synergy between human skills and AI makes fulfillment operations more scalable, efficient, and resilient.

- Advanced Replenishment and Reordering:

AI transforms inventory handling through automated replenishment systems, reducing manual reordering. These systems continuously monitor stock levels, compare them with forecasted demand, and automatically create purchase orders when stock hits preset thresholds. By automating routine reordering, businesses reduce human error and focus on strategic work. AI also optimizes order quantities and timing by considering supplier lead times, discounts, and storage limits, leading to smarter, more cost-efficient replenishment.

Simplify Warehouse and Logistics Management with ShipRelax

ShipRelax is a leading 3PL provider in the US, simplifying logistics and more for clients across the globe. We leverage an advanced, smart warehouse management system (WMS) named FulFillor to bring next-level efficiency to every phase of the logistics and supply chain process. The platform combines logistics, warehouse, inventory, labor, and fulfillment management in one unified platform, ideally perfect for modern supply chain businesses.

Transform Your Warehouse with AI-Powered Fulfillment

Unlock automation, accuracy, and real-time visibility in your supply chain with advanced AI-driven warehouse solutions.

Frequently Asked Questions

-

-

- How is AI used in warehouses?

-

AI is essentially used in warehouses to improve inventory management and order fulfillment. These two are the most crucial areas that boost overall productivity.

-

-

- How can AI improve inventory management?

-

Through automation, real-time visibility, and optimization capabilities, AI is used for inventory handling in multiple warehouse management systems.

-

-

- What do you mean by a smart warehouse management system?

-

A smart warehouse management system is a software application that integrates advanced technologies such as AI, robotics, IoT, automation, and other latest innovations to help organize logistics, warehouse, and fulfillment activities.